Northwest Compounders has worked with hundreds, maybe thousands, of brilliant and wonderful veterinary technicians over the years. Vet techs play a vital role in veterinary medicine and also serve as a critical medium between veterinarians and compounding pharmacies. Veterinary compounding is a very specialized field and can sometimes be difficult for techs, pharmacists and veterinarians to navigate. We’ve compiled a few useful tools to help clarify some of the most common questions we receive from vet clinics.

Preferred Liquid Dosing Volumes for Pets

Compared to humans, pets vary greatly in size, both between species and within their own species (especially dogs). This size variability creates a wide range of appropriate liquid dosing volumes that different-sized animals can tolerate. Generally speaking, the smaller the animal, the smaller the maximum liquid dosing volume. The following chart describes Northwest Compounder’s recommended liquid dosing volumes for different species based on our historic dispensing records.

| Species | Optimal Oral Liquid Dosing Range | Maximum Dosing Volume |

|---|---|---|

| Birds | 0.05mL-0.1mL | 0.1mL |

| Reptiles | 0.05mL-0.1mL | 0.1mL |

| Rodents | 0.05mL-0.1mL | 0.2mL |

| Rabbits | 0.1mL-0.2mL | 0.25mL |

| Ferrets | 0.1mL-0.2mL | 0.25mL |

| Cats | 0.2mL-0.5mL | 1mL |

| Small Dogs | 0.2mL-0.5mL | 1mL |

| Medium-Large Dogs | 0.2mL-1mL | 2mL |

| Horses | 5-15mL | 15mL |

Standardized Concentrations for Oral Liquids

In order to maximize efficiency and keep medication prices low, Northwest Compounders only offers the following concentrations for all compounded oral liquid medications:

| 1mg/mL | 5mg/mL | 20mg/mL |

| 2mg/mL | 10mg/mL | 50mg/mL |

| 2.5mg/mL | 15mg/mL | 100mg/mL |

Due to constraints caused by the chemical properties of some active pharmaceutical ingredients, there are maximum concentrations on most of our compounded oral liquids. Despite most constraints, there are a few products that can be made in concentrations of 200mg/mL, even up to 500mg/mL in the case of potassium bromide.

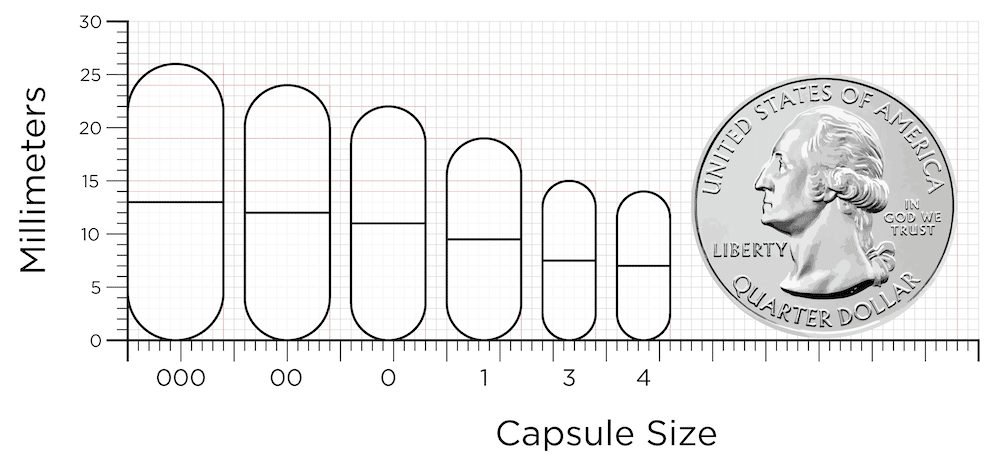

How Capsule Strength Translates to Capsule Size

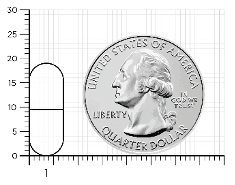

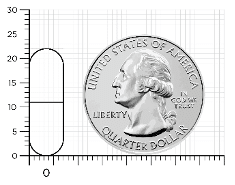

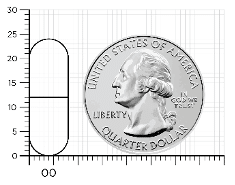

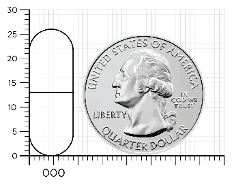

Capsules come in a variety of different sizes, some of which are too large for veterinary dosing:

The size of the capsule has the potential to greatly affect patient compliance. Administering a capsule size #1 or larger would be very difficult, if not impossible for cats and small dogs. Conversely, administering a very large dose to a large dog can be successfully done as a capsule size #00 or sometimes even #000. Because small capsules are always preferred in veterinary dosing, compounders will use a #4 capsule whenever possible. However, due to the spatial constraints of the tiny #4 size capsule, there are real limits on how much powder can fit inside. Active pharmaceutical ingredients vary substantially in their chemical properties. Powders exhibiting granularity or coarseness take up more volume compared to fine, fluffy powders. Variability in chemical properties and the patient’s desired dose are both factors that determine the size of capsule a compounder can use for a preparation.

The following table provides the best approximation of capsule size correlated to desired patient dose.

| Capsule Size | Size Comparison | Dose Capacity |

|---|---|---|

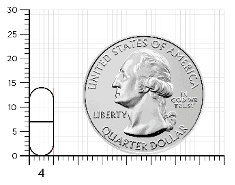

| #4’s |

| 0.1mg-150mg |

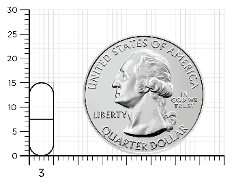

| #3’s |

| 120mg-200mg |

| #1’s |

| 170mg-350mg |

| #0’s |

| 320mg-500mg |

| #00’s |

| 350mg-1000mg |

| #000’s |

| 500mg-1200mg |

Dosing and Dispensing Transdermal Medications

Transdermal medications are an extremely useful dosage form whenever the patient is averse to oral routes of administration. Northwest Compounders offers two viable dispensing options for all of its veterinary transdermal products. Both options each have their own advantages to consider, but the pet owner’s input or preference should be the driving force in determining which option to go with. Choosing an option that the pet owner is comfortable administering will lead to better compliance and better outcomes. The table below highlights the two different options for transdermal dispensing that Northwest Compounders offers.

| Pre-Filled 1mL Syringes | Topi-CLICK Micro |

|---|---|

| Dosing volume of 0.05mL or 0.1mL | Dosing volume of 0.05mL (1 “click”) |

| No limit on dispense quantity, as long as day’s supply is within product BUD | Can dispense up to 9mL of cream in one Topi-CLICK Micro pen |

| Only whole-number 1mL increments are possible, i.e., 1 syringe, 3 syringes, 6 syringes, 12 syringes, etc. | Pet owner utilizes the built-in “click” mechanism of the Topi-CLICK Micro apparatus to dose 0.05mL with each “click” |

| Pet owner uses plunger on end of syringe to measure and dispense prescribed dose | Tip of Topi-CLICK Micro apparatus can be used to apply the medication directly to the patient without need for gloves |

| Gloves or finger cots should be utilized to prevent unwanted absorption into human’s skin | Apparatus should be wiped clean after every use |

| Variable dosing and exact dose titration can be utilized since owner can easily expel more or less cream from each syringe | Topi-CLICK Micro apparatus dispenses in 0.05mL increments only. |

| Syringes are provided at no extra cost to the customer | Topi-CLICK Micro are provided to customers by request with an additional charge of $5 per apparatus |

| Medication concentration is described as desired dose per 0.1mL on the prescription label (i.e 5mg/0.1mL) | Medication concentration is described as desired dose per click (0.05mL) (i.e 2.5mg/click (0.05mL)) |

Discounted Pricing for Larger Quantities

The most cost consuming process of compounding is labor. Generally speaking, nearly every order that a compounding pharmacy fulfills is made from scratch. We start with raw ingredients, typically powders and liquids, and manipulate them manually in a specified way to produce a unique dosage form product. This process is labor intensive and labor is always the highest cost line item when considering the cost of all of the ingredients that go into a compound. One excellent advantage to this process is that the same amount of labor is required to produce a one month supply, two month supply or a three month supply. This allows us to offer substantial price discounts when patients and pet owners order more than one month of medication at a time. Instead of making a patient’s prescription twice (once each month), we only have to make it once (for a two month supply). The only exception is when the active ingredient source of the compounded medication is expensive. This is a relatively rare occurrence, but is observed for a few specific drug ingredients.

Northwest Compounders receives a variety of calls from vet clinics with their compounding questions. A lot goes into the art of compounding, but the most common inquiries involve dosing volumes for pets, oral liquid concentrations, the correlation between capsule size and dosage, available dispensing options for transdermal medications and medication cost. We hope this overview provides you with a more in-depth look into these areas. If you’d like to learn more or have any questions, please call us at 503-352-3811 or send an email to info@northwestcompounders.com.